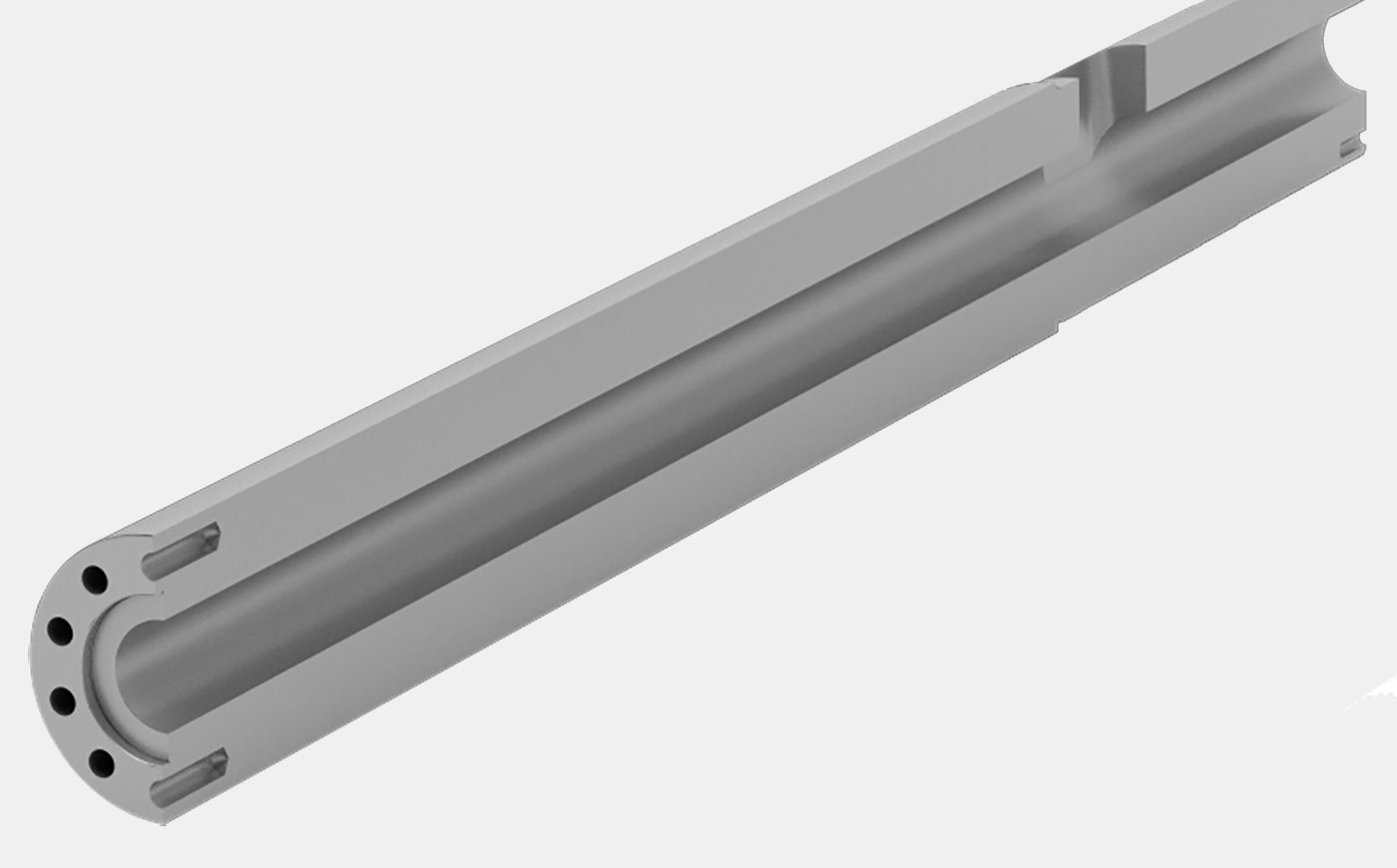

Barrels

If the plasticising screw is considered the soul of the injection unit, the barrel must be considered the body. The right choice of material to combat wear, corrosion resistance and give strength is of vital importance.

Why is a barrel important?

This component is extremely important, because it must be durable and give strength and support to all other components of the unit.

Bimetallic barrel

We offer a range of bimetallic barrels which cover the different classes of wear. Using centrifuge equipment of last generation the powders are distributed with efficiency in a homogeneous way and thus distortion-free and porosity, reaching roughness parameters min 0,15 µm, max. 0,8 µm. 0,15 ums to 0,8 ums. The working life of our bimetallic barrels varies from 5 to 10 times compared to that of a nitrided barrel.

Nitrided barrel

Standard Barrels: this type of material is used for the transformation of polymers that do not determine abrasive and corrosive wearing. Our ongoing research in improving production led us to select the best steel. This material needs to be hardened with nitriding thermic treatment.

Gas nitriding

We generally use NT5 72H type in vertical, by which we will have a hardness of 1000-1050 HVs for a depth of 0,4-0,5 mm. It is also possible to reach hardness and depth depending on the length of exposure to the treatment. The vertical position of barrels guarantees uniformity of application with consequent homogeneity of the nitriding area.

Ionic nitriding

We apply this treatment to the material where we must have hardened, not fragile homogeneous surfaces. Besides it gives stability to the material eliminating internal stress (cause of fracture and cracking) The permeability of the treatment reaches 0,8 mm. with hardness 1000-1100 HVs.